Casting

The following page of notes will cover:

- Sand casting

- Investment casting

- Die casting

- Resin casting

- Plaster of Paris casting

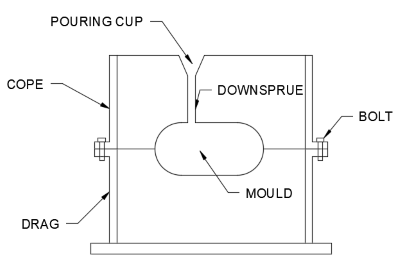

Sand casting:

How it works:

- Make a mould in the sand using to half moulds (cope and drag) making sure the corners are rounded/tapered

- Fix the cope and drag together with nuts and bolts

- Pour molten metal into case

- Let it cool and remove mould

- Apply finishes

| Advantages | Disadvantages |

|---|---|

|

|

Uses: Engine blocks, garden furniture, caterpillar tracks

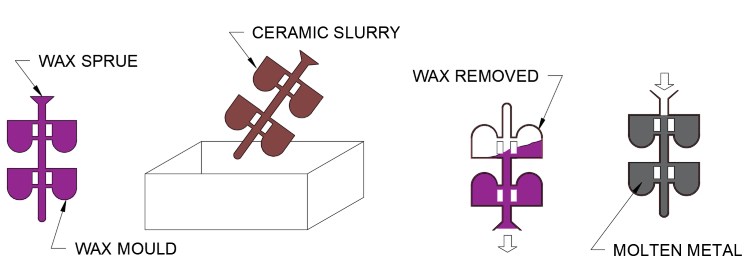

Investment casting:

How it works:

- Cold wax mould made of desired shape

- Wax mould attached to sprue before being dipped into liquid ceramic/stucco

- Then heated to remove wax and set ceramic

- Molten metal is then poured into the cermaic mould and allowed to set

- Ceramic shell is then broken off revealing product

| Advantages | Disadvantages |

|---|---|

|

|

Uses: Turbine blades, gears, machine parts

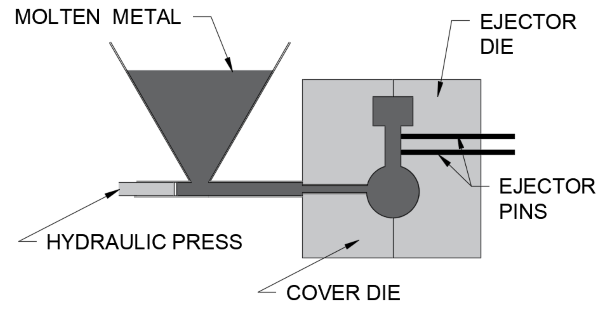

Die casting:

How it works:

- Create and lubricate the mould

- Once mould has been created, molten metal is shot under high pressure into the die

- When the die is full, the pressure is maintained until the metal has solidified

- The mould is then removed and finishes are applied

| Advantages | Disadvantages |

|---|---|

|

|

Uses: Taps, model cars

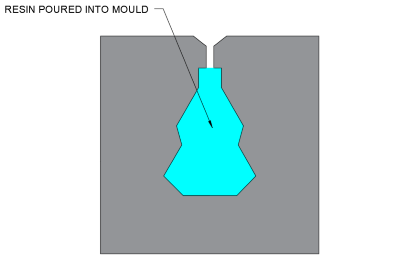

Resin casting:

How it works:

- Mould made of desired shape

- Liquid synthetic resin poured into mould

- Resin hardens and the mould is removed

| Advantages | Disadvantages |

|---|---|

|

|

Uses: Collectible toys, models, figures, smallscale jewellery

Plaster of Paris casting (gypsum):

How it works:

- Mix the formula with water

- Poor into mould

- Allow to set

| Advantages | Disadvantages |

|---|---|

|

|